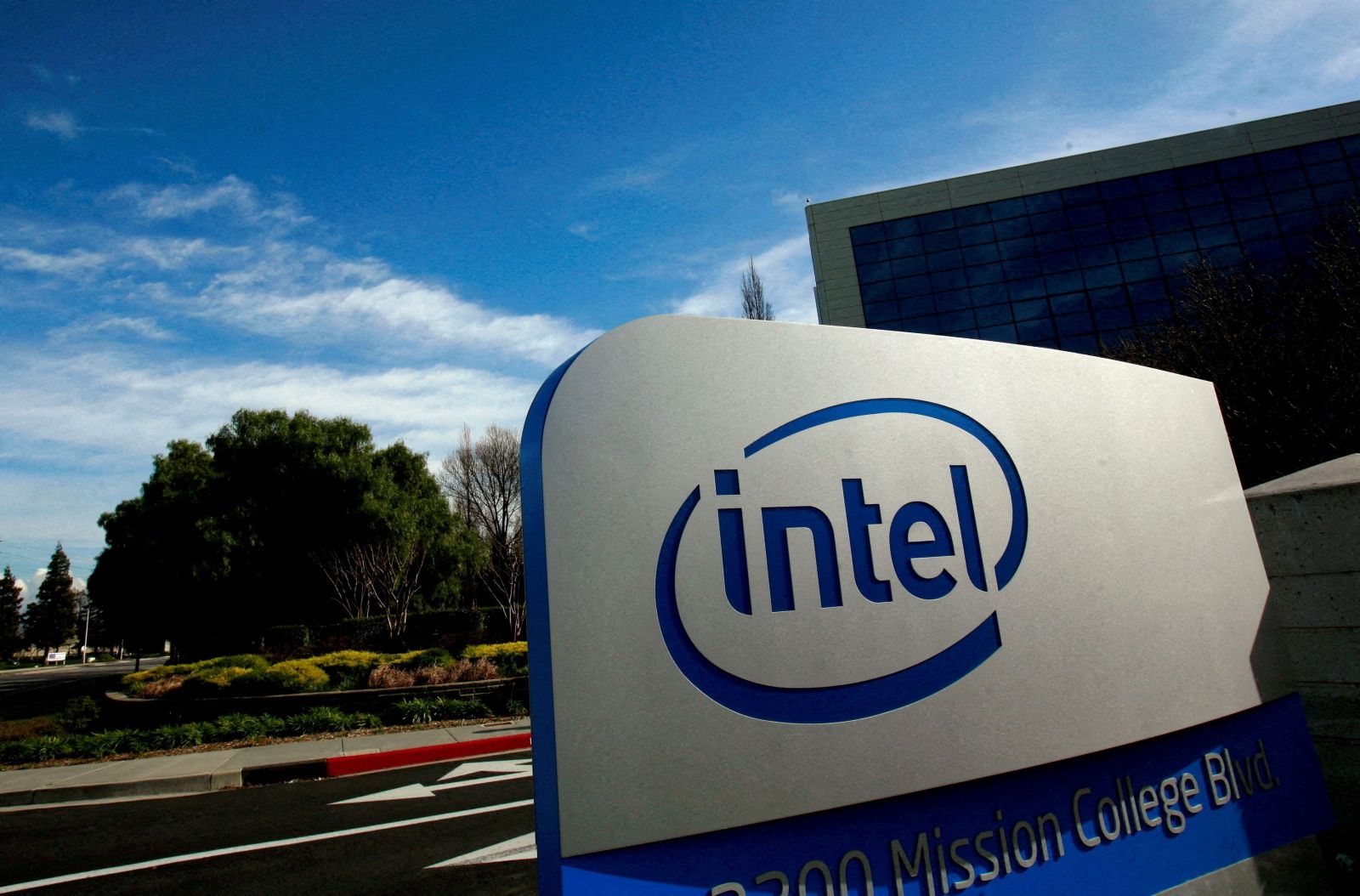

Lack of innovation, ignoring mobile wave, missing AI boom: Why Intel is struggling

Once the world’s most dominant designer and manufacturer of computer chips, Intel has become a shadow of itself in recent years, struggling to keep up with industrial rivals. Here is the story of what went wrong with Intel

A sign is shown at the entrance to the headquarters of Intel Corporation in Santa Clara, California. (Photo: Reuters)

A sign is shown at the entrance to the headquarters of Intel Corporation in Santa Clara, California. (Photo: Reuters)

American chipmaker Intel’s new CEO Lip-Bu Tan on Thursday announced that the company would soon implement significant spending cuts that would also involve laying off its employees. Although Tan did not give the details about the number of employees affected, Bloomberg reported that Intel might slash more than 20% of its workforce (around 21,000 employees).

The CEO also announced that the company had posted a loss of $800 million on revenue of $12.7 billion in the first three months of this year. In 2024, Intel reported a net loss of $18.8 billion, its first since 1986. Last year, the company laid off some 15,000 employees.

Once the world’s most dominant designer and manufacturer of computer chips, Intel has become a shadow of itself in recent years, struggling to keep up with industrial rivals such as Nvidia, Taiwan Semiconductor Manufacturing Co (TSMC), and Advanced Micro Devices (AMD). Here is the story of what went wrong with Intel.

Business trumps engineering

Intel’s problems began when Paul Otellini became the CEO of the company in 2005. It was a departure from the norm as Otellini was the first non-engineer Intel CEO, mainly rising through the company’s sales and marketing ranks.

Otellini was chosen for his ruthless anti-competitive business decisions. For instance, he enacted a policy in Intel that involved paying companies such as Dell to not use AMD, which severely impacted AMD’s revenue, R&D, and fabrication investments.

This led to a major shift in Intel’s work culture. “Intel had a harsh way of getting things done, but it was a productive culture. Paul Otellini changed this. Technical decisions were pushed aside for political power, and the path forward throughout the company was through power struggles among the various fiefdoms,” according to a report by SemiAnalysis, an independent research and analysis company.

Even after Otellini’s retirement in 2013, the “toxic” culture continued under the leadership of future CEOs such as Brian Krzanich (2013-2018) and Bob Swan (2019-2021).

As a result, innovation took a backseat at the company, and experimental ventures were killed off if they did not immediately contribute to revenue or risked cannibalising existing products.

During these years, Intel made catastrophic mistakes. It ignored the mobile chip boom, failed to successfully adopt extreme ultraviolet (EUV) lithography — a type of chip manufacturing process — and missed the artificial intelligence transition.

The missteps ultimately came back to haunt the company in 2022 when its revenues started to plunge (it dropped to $63.1 billion from $79.0 billion in 2021), and continue to do so even today (in 2024, the revenue was $53.1 billion).

Ignoring the mobile chip boom

Intel first fumbled the ball just before the proliferation of mobile chips which was triggered by the launch of Apple’s iPhone in 2007.

According to Walter Isaacson’s 2011 biography ‘Steve Jobs’, Apple’s then CEO Jobs met Otellini to discuss whether Intel should power the yet-to-be-released iPhone. At the time, Intel chips were already running some of the best personal computers (PCs) in the world, including Apple’s Mac.

However, Jobs and Otellini could not broker a deal over the iPhone. While Jobs said that Intel chips were “slow”, Otellini claimed that the two CEOs could not agree on a price or who owned the intellectual property, according to Isaacson.

Steve Jobs presented Intel CEO Paul Otellini with a custom-designed award in 2007. (Photo: Wikimedia Commons)

Steve Jobs presented Intel CEO Paul Otellini with a custom-designed award in 2007. (Photo: Wikimedia Commons)

Apple released the first iPhone with a chip which was manufactured by Samsung, and designed by a relatively unknown British company called ARM. Within the next five years, Apple was shipping millions of iPhones annually, and smartphones became the next big thing (smartphone shipments surpassed PC shipments in 2010), giving users many of the perks of a PC in their pocket.

Today, ARM-designed chips are in almost every smartphone. Not only this, these chips have now replaced Intel processors in PCs as well including those manufactured by Apple. Intel could never catch up to the British company for two reasons.

One, it did not provide enough to its team working on low-power Atom chips for mobile phones in the early 2000s. Two, the company’s renowned x86 technology, which was created for PCs in 1981 and is still in use, could not compete with the efficiency of ARM-designed chips.

Failure to adopt EUV lithography

Over the last half-century, companies have built more powerful and faster chips or processors by adding more transistors (each one allows them to do more calculations) on them. For instance, Intel’s first microprocessor, the 4004, which was launched in 1971, had about 2,000 transistors. Now, the company’s chips have billions of transistors.

Intel’s 4004

Intel’s 4004

However, to add more transistors, there is a need to shrink them in size. Currently, the best chips in the market come with transistors which are just 3-nanometre in size.

In the initial decades, Intel was able to regularly deliver smaller transistors but by 2015, this process began to stumble. That year, then CEO Krzanich announced that the shipping of the company’s 10 nm chips would be delayed, and it would continue shipping 14 nm processors for longer than the normal two years. The delays compounded, and Intel missed deadlines for its 7 nm chips as well.

One of the primary reasons for these delays was that Intel did not successfully adopt EUV lithography, which is a complex technology that has been instrumental in the shrinking transistor size in recent years. Notably, the EUV lithography machines are only manufactured by Dutch company ASML which received funding from Intel in the late 1990s and early 2000s.

Sources told Yahoo Finance that Intel had 10 such machines worth $1 billion but did not fully utilize them. Meanwhile, Samsung and TSMC embraced these machines and manufactured cutting-edge chips.

“TSMC didn’t have the same issues with 10 nm or 7 nm, and that meant that AMD’s [the company designs its own chips but relies on TSMC to manufacture them] chips were competitive or better than Intel’s in the latter half of the decade [2010s], especially for certain tasks,” according to a report by CNBC.

Credit: Wikimedia Commons

Credit: Wikimedia Commons

This helped AMD quickly eat into Intel’s market share, especially in server CPUs that provide higher computing power.

Missing AI transition

At the heart of the ongoing AI proliferation are graphics processing units (GPUs), which are used to train AI models. Although GPUs were originally developed for graphics rendering in gaming and animation, researchers soon realised that they could be more efficient than CPUs at handling the intensive data crunching necessary to build and train large AI models.

However, for more than two decades, Intel engineers did not believe in the potential of GPUs. They saw these processing units — used by Nvidia and AMD — as “ugly” versions of CPUs, according to a report by Reuters.

Nvidia, on the other hand, used these years to modify the GPU architecture to tune them for AI uses, and built the software necessary to harness the capabilities.

“When AI hit … Intel just didn’t have the right processor at the right time,” Lou Miscioscia, an analyst at Japanese investment bank Daiwa, told Reuters.

Also, Intel missed the chance to buy a stake in OpenAI in the late 2010s when the latter was just a fledgling non-profit research organisation. Between 2017 and 2018, executives at the two companies discussed various options but Intel decided against a deal, partly because then CEO Swan thought that generative AI would not make it to market in the near future.

OpenAI released its groundbreaking ChatGPT in 2022, and is currently valued at around $157 billion.

Uncertain future

The ongoing trade war between China and the US has worsened the situation for Intel. While President Donald Trump for now has spared chips from tariffs, China has said US-manufactured semiconductors are set to face levies of 85% or higher.

China imports $10 billion worth of chips from the US every year. Around $8 billion of these are CPUs assembled by Intel in the US.

On Friday, some reports suggested that Beijing had rolled back retaliatory tariffs on US-made semiconductors but an official announcement was yet to be made. Such developments have no doubt created more uncertainty about Intel’s future.

The company’s CFO David Zinsner on Thursday said tariffs had increased the chance of an economic slowdown with the probability of a recession growing. “This makes it more difficult to forecast how we will perform for the quarter and for the year,” he also said.

Intel’s best hope to turn around its fortunes seems to be a likely collaboration with TSMC. The two companies are reportedly discussing forming a joint venture to operate Intel’s chip manufacturing factories in the US. On Thursday, CEO Tan said he had met TSMC’s CEO C C Wei about the possible deal.

However, so far, there has been no official indication from TSMC about such a venture with Intel.